Steel skeleton PE composite pipe

Steel skeleton PE composite pipe is a new type of pressure-resisting pipe, which is formed by extrusion and extrusion with welded mesh steel wire skeleton as reinforcement and thermoplastic as continuous base material. This technology uniquely combines the advantages of steel structure, strength and polyethylene pipe, resulting in unparalleled hydraulic pressure and length of pipe. Structural performance of the period. Successfully applied all over the world, steel skeleton polyethylene composite pipe has a life of more than 25 years, after several years of rigorous field testing. The pipe is mainly suitable for medium pressure pipeline, submarine laying pipeline and electric (optical) cable conduit in the fields of petroleum, natural gas, chemical industry, municipal administration, communication and ship.

Pipeline performance

Anti-corrosion ability

Raw materials use PE and steel strip, PE composite pipe all have PE acid and alkali resistance. Anti-corrosion performance, no need to do anti-corrosion treatment while in installation, less man power costs.

Connection type

Pipeline connection adopts electrothermal fusion connection, which is mature in technology and complete in pipe fittings specifications. It is convenient to construct and low in comprehensive cost.

Advantages

With good Rigidity and flexibility, good creep resistance, good impact resistance, good resistance to rapid cracking, small thermal expansion coefficient, good self-traceability.

Resistance and pressure

The inner cavity is smooth, the friction coefficient is 0.009, and the circulation capacity is large. The tensile strength of the steel wire is 1800MPa, and the compressive strength of the pipe under load has obvious advantages.

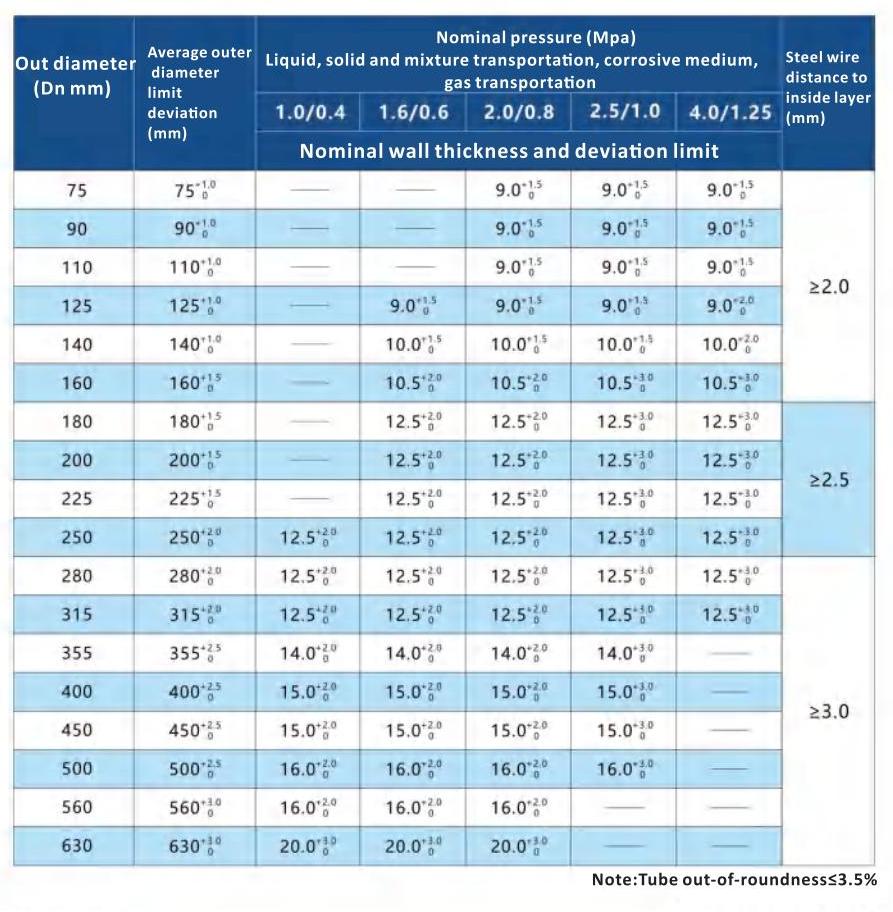

Pipe Specifications