Stell wire mesh skeleton pe composite pipe

Steel wire mesh reinforced plastic composite pipes are widely used in pressure composite piping systems in industries such as industry, urban water supply, petroleum and gas, chemical industry and agriculture. The company’s wire mesh reinforced composite pipe production line has a number of patented technologies. The production line can use high-strength wire such as high-strength steel wire, glass fiber bundle, polyester fiber and other high-strength wires to produce high-strength composite plastic pipes, but also can produce pure polyethylene pipes for water supply and gas in line with national standards, which truly realizes a multi-functional machine. Reduce the cost of reinvestment of your equipment. Its pipe standards meet the standards of CJ/T189-2007 and GB/T32439-2015, and its corresponding construction regulations and components have matured. Its production, sales and promotion and application have gradually embarked on the road of industrial development, and it has become the main product in the field of composite plastic pipes.

Product Characteristics

Raw materials used

High-density polyethylene inside, outside reinforced with high strength wire mesh, excellent performance of pipe, high working pressure.

Hydraulic characteristics

The inner wall is smooth (pipe wall roughness is about 0.007), the matrix material HDPE is a non-polar substance, the pipe wall does not scale, the flow capacity is strong, and the conveying capacity is about 30% higher than that of the steel pipe.

Anti-corrosion performance

The inner and outer walls of the Steel wire mesh skeleton PE composite pipe are made of high-density polyethylene plastic as the matrix; it has double-sided anti-corrosion characteristics, good acid resistance, alkali resistance, chemical corrosion resistance, and excellent soil electrochemical corrosion resistance.

Sealing performance

Connection method: Utilize the thermoplastic principle of high-density polyethylene, and use electric heat to connect. The pipe network is successfully connected once, never leaks, with excellent sealing performance.

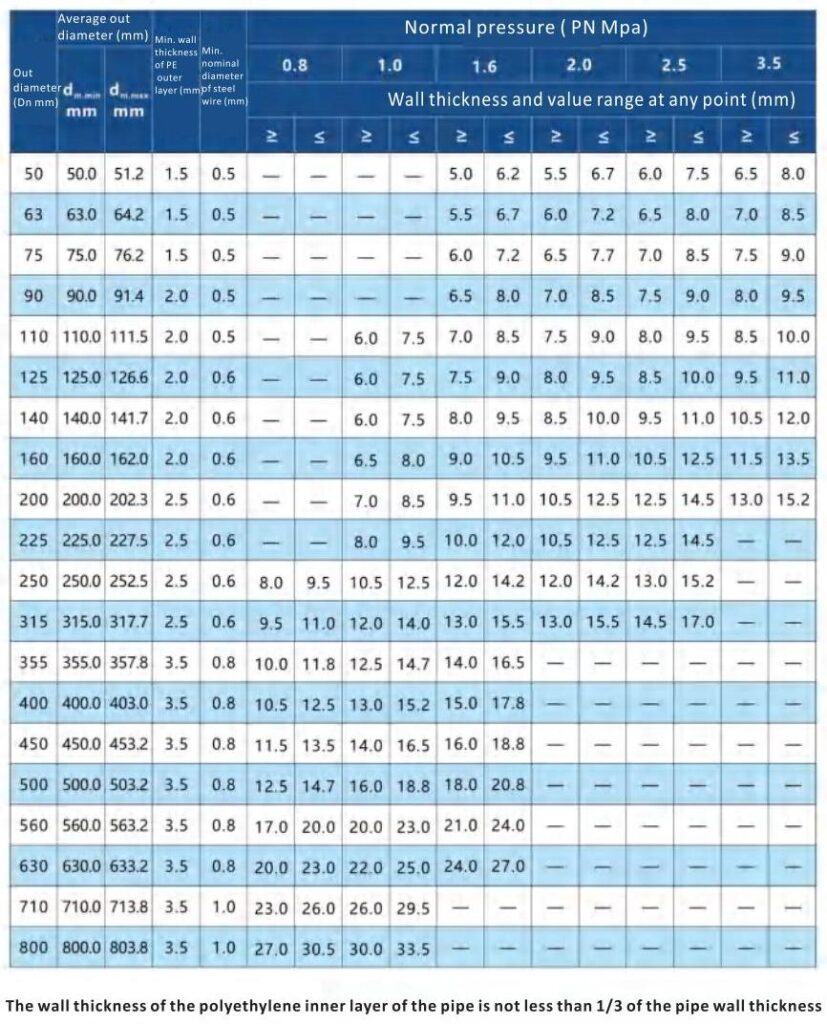

Pipe specifications

Project construction:

Choose electric fusion pipe fittings and flange connection.

Flexible pipelines have corresponding bends. Pipe fittings are not required for bends with an angle of less than 15 degrees. The construction of complex and fluctuating terrain is convenient and the geological and environmental adaptability is strong.

The trenches are made of soft pipes and are not disposed of, and no special design scheme is required. The construction is simple and clear.

- The entire working pressure of the pipe is mainly acted on the steel mesh lifting layer whose elastic modulus far exceeds that of PE (the elastic modulus of steel wire is 200 times that of PE material). The pipeline has the compressive strength characteristics of metal pipes, but also preserves the plastic pipe’s Soft features (radius of curvature greater than 75).

Cross steel wire mesh to get rid of stress cracking and creep of PE material reasonably.

No fouling in the inner cavity